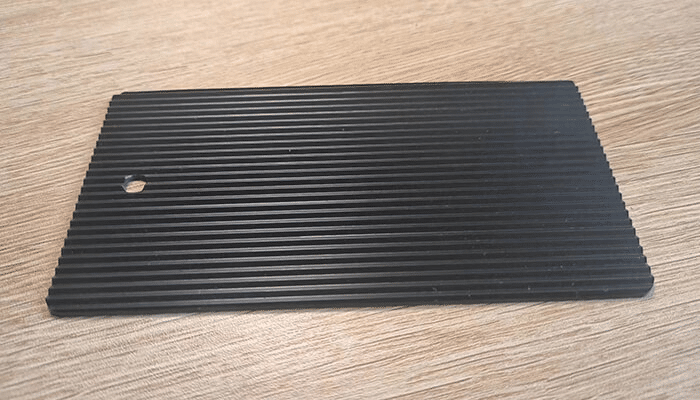

If you’ve ever wondered why some materials last longer under constant friction, the answer often lies in their composition. Acetal plastic sheets are widely recognised for their ability to handle wear and tear without losing performance.

From machine parts to everyday components, they’ve become a trusted choice for industries that rely on durability. Keep reading to see why this material deserves attention when reliability matters.

Excellent Durability Under Friction

One of the strongest advantages of acetal plastic sheets is their resistance to wear caused by friction. Unlike softer plastics, acetal keeps its surface smooth even after repeated movement against other parts.

This makes it useful in applications like gears, bearings, or conveyor systems, where constant contact can easily degrade weaker materials. By holding its structure, acetal extends the service life of parts and reduces replacement costs.

Strong Dimensional Stability

When you’re designing parts that need precision, even a slight shift can cause failure. Acetal plastics give you dimensional stability, meaning they stay true to their intended measurements over time.

This quality ensures machinery parts fit together correctly, reducing the chance of breakdowns or costly downtime. For manufacturers producing high-volume components, this stability also helps keep quality consistent across every batch.

Reliable Moisture Resistance

Another reason engineers prefer this material is its low moisture absorption. Some plastics weaken or change size when exposed to water, but acetal maintains its shape and strength.

This is particularly important in the damp climate, where high humidity often causes swelling or warping in other plastics. With acetal, you don’t have to worry about that risk, making it a reliable option for outdoor or semi-exposed environments.

Impressive Load-Bearing Capacity

Acetal sheets can handleheavy loads without deforming. In industries where constant pressure is placed on components, such as automotive, aerospace, or manufacturing, this strength is vital.

The material distributes stress effectively, keeping performance consistent even under demanding conditions. For designers and engineers, this ability to manage weight without losing form is one of the key reasons to choose acetal.

Low Coefficient of Friction

A defining feature of acetal plastics is their naturally low coefficient of friction. This means parts made from the material move smoothly without the need for excessive lubrication. For industries trying to cut maintenance costs, this feature is a real advantage.

It also reduces noise during operation, which can improve both safety and comfort in workplace settings such as production lines.

Chemical and Wear Resistance Combined

Many environments expose materials to both physical wear and chemicals. Acetal sheets offerprotection against solvents, fuels, and cleaning agents, all while maintaining their resistance to wear.

This balance of strength makes them dependable in harsh industrial settings where other plastics might fail. For sectors like food processing or healthcare, where cleaning agents are unavoidable, this combination of resistance ensures both performance and hygiene.

Closure

Acetal plastic sheets stand out because they combine wear resistance, dimensional stability, moisture control, and chemical toughness. These qualities make them highly valued for industries that depend on reliability and long-term performance. If you’re searching for a material that works under pressure without giving in, acetal is a smart choice that won’t let you down.