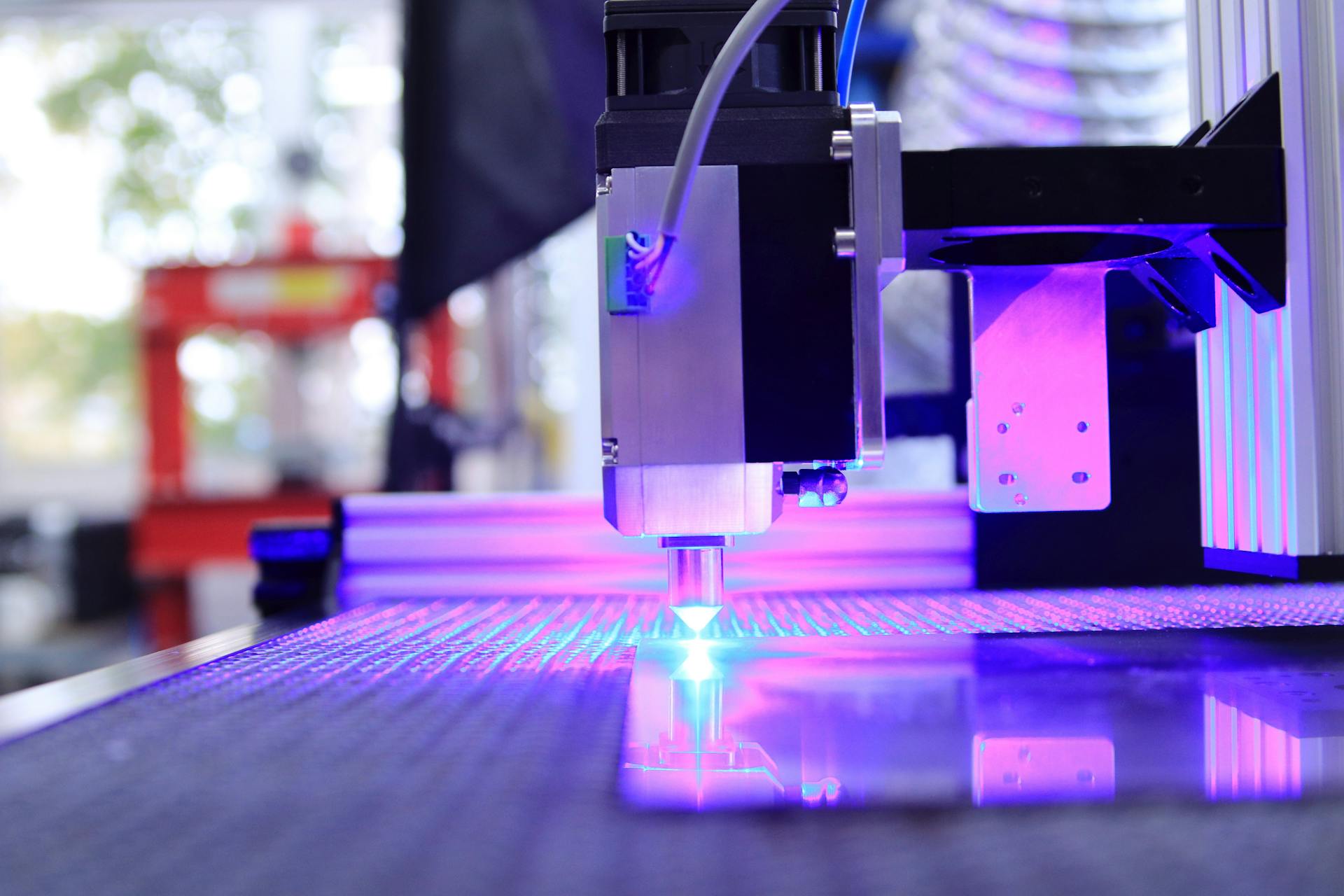

Many programmers can relate to watching a perfectly calculated toolpath crash into a fixture at 3 AM. The simulation may look flawless, the G-code may check out, yet a programmer can still be staring at a damaged part and a bent tool holder. Sound familiar?

The thing is, most CAM systems still program like it’s 1995. They calculate beautiful toolpaths around the part geometry, generate clean code, and call it a day. But here’s what they’re missing: your actual machine.

The Fundamental Flaw in Traditional CAM

Traditional CAM programming treats a million-dollar 5-axis machining center like a theoretical point in space that magically moves a cutting tool. It focuses on the tooltip’s journey around the workpiece, completely ignoring what the rest of the machine is doing.

Think about it. When a programmer programs a complex undercut on a turbine blade, legacy systems calculate the perfect tool angle and path. Great! Except they don’t account for:

- Whether the rotary axes can actually reach those positions without hitting limits

- If the tool holder will collide with the fixture halfway through the operation

- How the workpiece looks right now after the previous operations

- Whether that beautiful simultaneous 5-axis move will push the machine into a singularity

The result? Programmers spend hours in trial-and-error mode, tweaking offsets, adjusting fixture positions, and praying the next simulation run doesn’t reveal another collision.

What Machine-Aware Programming Actually Means

Machine-aware CAM isn’t just a buzzword (though marketing teams love throwing it around). It’s a fundamentally different approach to generating toolpaths.

Instead of asking “How should the tool move around this part?”, machine-aware systems ask “How will this specific machine need to move to machine this part safely and efficiently?”

Real machine limits, not theoretical ones

The machine’s axis travel limits aren’t suggestions. When programming a large aerospace component, the system should know whether your table can actually rotate to -120 degrees or if a programmer will need to reposition the part. Seems obvious, right? Yet most CAM packages treat these limits as afterthoughts.

Holder awareness that actually works

Programmers are often observed spending entire afternoons manually checking holder clearances because their CAM system only verified the cutting edge. Machine-aware programming considers the entire tool assembly – collet, holder, extension – from the start. It calculates movements based on real geometry, not just the theoretical cutting diameter.

Live stock tracking

Here’s where things get interesting. After roughing operations, the stock isn’t a perfect cylinder anymore. It’s got valleys, shoulders, and irregular surfaces. Machine-aware systems update the virtual stock model after each operation, generating subsequent toolpaths based on what’s actually there, not what was supposed to be there.

The Performance Gap Nobody Talks About

To illustrate the impact, data from shop floors often shows programming time for a series of complex 5-axis parts:

Legacy CAM approach: 8-12 hours of programming and verification per part, with 2-3 fixture redesigns per project to avoid collisions that weren’t catchable in simulation.

After switching to machine-aware programming: 3-5 hours total, virtually zero surprise collisions, and – here’s the kicker – 23% reduction in cycle time because the system optimized movements based on the machine’s actual acceleration curves and axis speeds.

That’s not a marginal improvement. That’s the difference between being profitable on a job or not.

What Modern Solutions Look Like

The industry has finally started catching up. Platforms like ENCY CAD/CAM have built their entire architecture around machine-aware concepts. Instead of bolting collision detection onto traditional CAM algorithms, they calculate actual machine movements from the ground up.

What does this mean practically?

Kinematics-first approach

The system models the machine’s kinematic behavior – how the axes interact, where singularities occur, how rotary movements affect positioning accuracy. Programming becomes a conversation with the actual equipment, not an abstract exercise in geometry.

Integrated digital twins

Forget manually measuring the fixture setup and hoping the CAM model matches reality. Modern machine-aware platforms maintain digital twins of your entire setup. When a user programs, they are working with a virtual replica of your real machine, complete with its quirks and limitations.

Collision avoidance that thinks ahead

Rather than just checking for intersections, smart systems optimize the entire toolpath to avoid potential collisions while maintaining efficiency. It’s like having an experienced programmer looking over the user’s shoulder, except it happens automatically during calculation.

The Skills Gap (And Why It’s Shrinking)

The argument is often heard: “Machine-aware programming requires too much expertise to set up.”

This was arguably true in the past. Early implementations demanded deep knowledge of machine kinematics and required programmers to manually configure complex parameters.

But here’s what changed: the software got smarter about handling complexity while exposing simpler interfaces. Programmers still need to understand their machine, but they don’t need a PhD in robotics to program it effectively anymore.

The real skills gap now isn’t technical – it’s conceptual. Programmers trained on legacy methods sometimes struggle to shift their mental model from “programming toolpaths” to “programming machine movements.” It’s not harder; it’s just different.

Making the Transition

If a shop is still using traditional CAM methods, the transition might feel daunting. Key factors for a successful transition are:

Start with your digital twins

Get accurate models of the machines and tooling. This isn’t optional – it’s the foundation everything else builds on. Most modern CAM platforms include libraries of common machine configurations, so shops are not starting from scratch.

Embrace verification as programming, not aftermath

In machine-aware workflows, verification isn’t something that is done after programming. It’s integrated into the process. Programmers see potential issues as they work, not after they’ve invested hours in a toolpath strategy.

Trust the automation (gradually)

Let the system optimize movements and handle collision avoidance for routine operations. Save human expertise for the truly complex stuff that requires human judgment.

Where This Goes Next

Machine-aware programming isn’t the end goal – it’s the foundation for what’s coming. AI-driven optimization, adaptive machining based on real-time sensor data, and cloud-based collaborative programming all depend on having accurate machine models and kinematics-aware systems.

The shops that adapt to machine-aware methods now aren’t just improving their current operations. They’re positioning themselves for the next generation of manufacturing technology.

The Bottom Line

Traditional CAM served the industry well for decades. But as parts get more complex, machines get more sophisticated, and competition gets fiercer, the old “program-and-pray” approach doesn’t cut it anymore.

Machine-aware programming isn’t about adding features to an existing workflow. It’s about fundamentally rethinking how the industry generates machine movements. The transition takes effort, sure. But the alternative – continuing with methods that ignore the reality of the actual equipment – is increasingly expensive.

The CNC machine isn’t a theoretical construct. It’s a real machine with real limitations and real capabilities. Isn’t it time programming software treated it that way?