Choosing between CNC routing and laser cutting can seem tricky when both deliver precise and professional results. Each method shapes materials differently, affecting the finish, speed, and flexibility of your final product.

Both techniques are widely used in fabrication and design, but the right choice depends on what you want to achieve in terms of quality, efficiency, and cost. Knowing how they compare helps you make a smarter choice and achieve the outcome you want for your project. Carry on reading to see which method gives you better results.

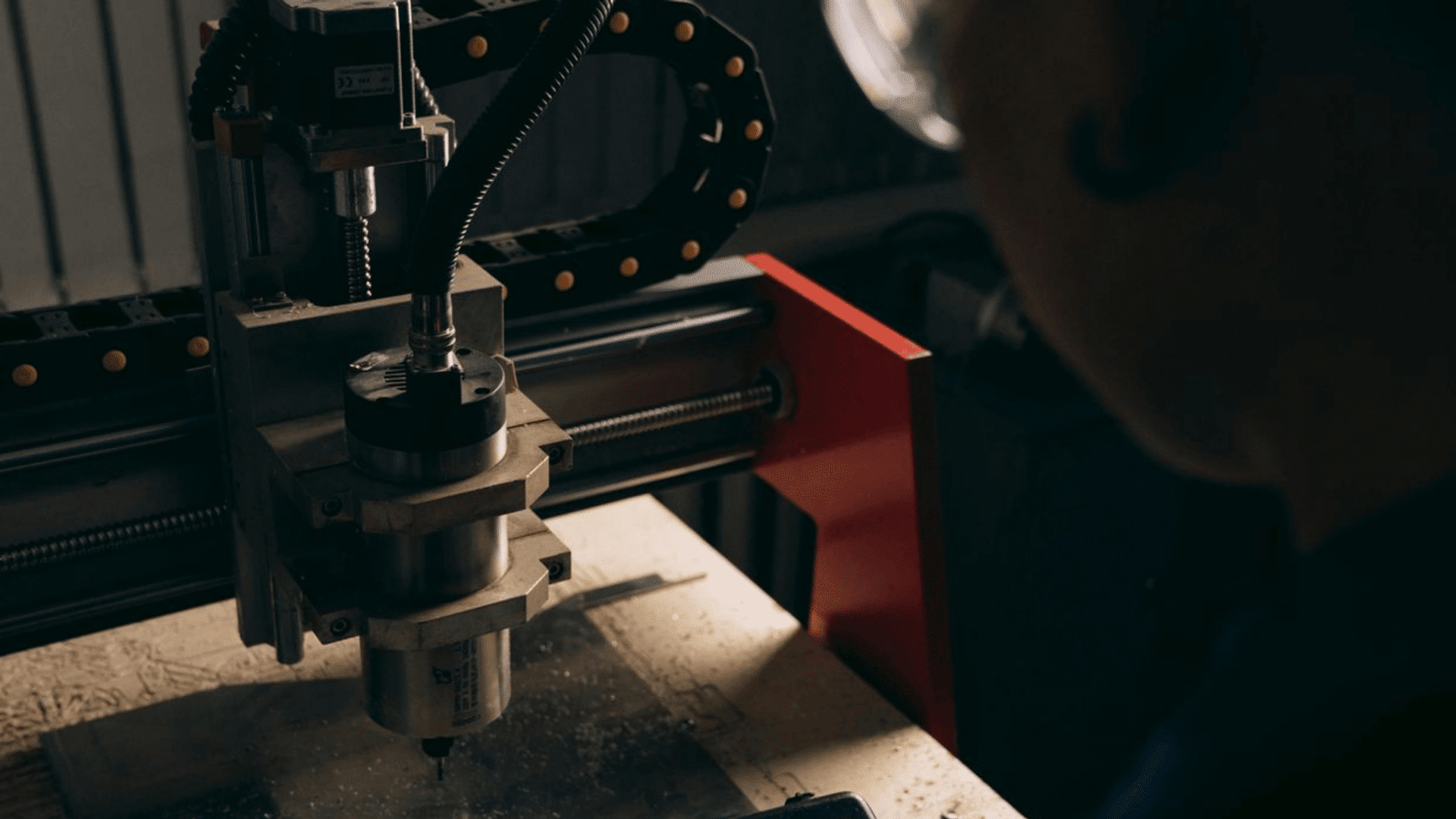

How CNC Routing Works And Why It’s Reliable

CNC routing relies on a rotating cutting tool controlled by computer software. It removes material layer by layer, giving you complete control over depth and shape. Because it’s a physical cutting process, it handles thicker and tougher materials such as acrylic, PVC, polycarbonate, and aluminium composite panels with ease.

A dependable CNC routing service is ideal for anyone needing accurate results and strong, consistent finishes. You can use it for sign making, industrial parts, architectural panels, or even decorative projects. Since the router can switch tools during cutting, it can also shape edges, drill holes while maintaining uniform precision.

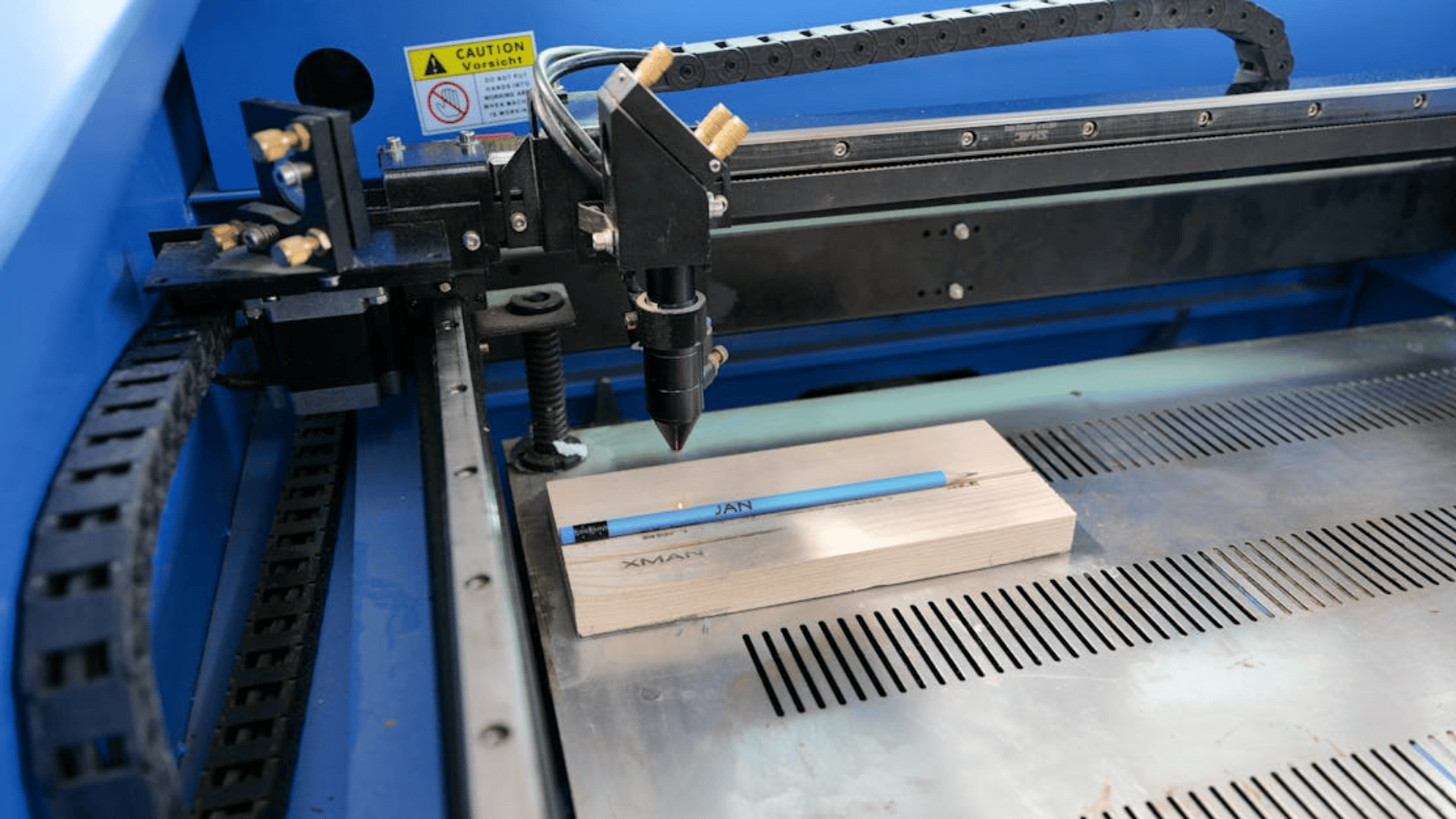

How Laser Cutting Achieves High Precision

Laser cutting uses a focused beam of light to slice through material, creating clean and detailed edges. Because it doesn’t rely on physical contact, the process can produce fine lines and intricate designs with minimal distortion. It’s especially effective on thinner sheets of acrylic, wood, and plastics, making it a popular choice for signage, retail displays, and detailed patterns.

However, the heat from the laser can slightly alter the edges of thicker materials, leaving a glossy or discoloured finish. While this can be desirable in some cases, projects that demand even texture or deeper cuts are often better handled with CNC routing.

Precision, Material Range, And Versatility

When it comes to precision, laser cutting usually delivers finer detail. It’s perfect for lettering, small decorative pieces, or complex outlines that require tight tolerances. CNC routing stands out for its strength and versatility. It cuts deeper and supports a broader range of materials without warping or burning.

If your project requires engraving, shaping, or contouring, CNC routing offers far greater flexibility. Laser cutting provides a near polished finish on acrylics, but routers can create various edge styles depending on the tool used.

Speed, Finish, And Cost Factors

For thin sheets and simple outlines, laser cutting often works faster since it doesn’t use physical tools. But for thicker plastics or layered materials, CNC routing is more efficient and avoids issues like melting or heat damage. The router’s multi tool capability also allows for deeper or more complex designs without slowing production.

The finish depends on what you’re after. Laser cutting gives smooth, flame polished edges ideal for display work. CNC routing leaves a crisp edge that can be polished later for a clean, or glossy look. Cost wise, laser cutting tends to suit smaller, intricate jobs, while CNC routing is usually more economical for large scale or high strength fabrication.

Choosing The Method That Suits You Best

Your choice depends on what matters most, whether it’s detail, strength, or scale. If you’re producing intricate signage, decorative panels, or precise shapes from thin material, laser cutting is the practical option. But if you need durability, variation in depth, CNC routing provides a more stable and adaptable solution.

Some projects even benefit from combining both methods. Laser cutting can handle the detailed components, while CNC routing manages the structural elements, resulting in a balanced and high quality finish.

A Smarter Approach To Better Fabrication Results

Both CNC routing and laser cutting play valuable roles in modern fabrication. Laser cutting excels in fine detailing and surface clarity, while CNC routing offers depth, durability, and design flexibility.

By understanding how each method performs across different materials and applications, you can select the one that saves time, reduces waste, and ensures your finished piece meets your expectations every time. Choosing the right process not only improves your results but also helps you create stronger and more sustainable products that stand out for their quality and precision.